Rayblewit

Love Music / Love Life

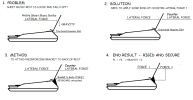

My keyboard sheet music REST or STAND (whatever you call it) has become very loose and falls off!

It falls backwards out of its housing slots.

I worked out where the problem is . . The main housing (slots) of the KEYBOARD has cracks where the REST locks in.

I am guessing it is old age or maybe has been overloaded too many times with heavy music books.

I took a couple of snaps . . . can you see the cracks?

Any clues how to fix?

I reckon I will not get many responses, however thanks in advance for even reading this to this point.

It falls backwards out of its housing slots.

I worked out where the problem is . . The main housing (slots) of the KEYBOARD has cracks where the REST locks in.

I am guessing it is old age or maybe has been overloaded too many times with heavy music books.

I took a couple of snaps . . . can you see the cracks?

Any clues how to fix?

I reckon I will not get many responses, however thanks in advance for even reading this to this point.